Postion: Home > Our Case > Stamping & Bending >

CATEGORIES

CATEGORIESWhether you're launching a new product or scaling up mass production, Hongming Sheng offers precision-crafted stamping solutions tailored to your needs. With over 15 years of experience and clients in 30+ countries, we are the trusted partner for global manufacturers.

we has the capability to do high-speed stamping at over 1,000 parts per minute, with optional reel-to-reel material handling.

State-Of-The-Art Process

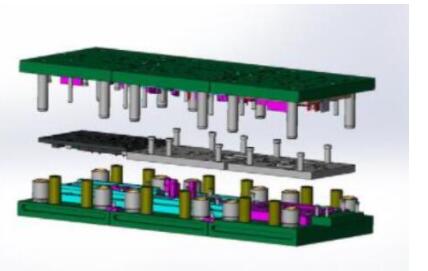

Tooling design & Tooling manufacture

Quality stamping tools are key to a quality metal stamping. This principle is the foundation of we stamping's sucess, and is reflected in every aspect of our tooling operations, all of which are performed in-house.

Quality stamping tools are key to a quality metal stamping. This principle is the foundation of we stamping's sucess, and is reflected in every aspect of our tooling operations, all of which are performed in-house.

To design our stamping tools, we utilize the lastest CAD software tools and Solidworks to create files that aer fed directly to our Wire EDM and CNC machining centers, without operator invention. After the componnets are finished, our skilled toolmakers perform the final tooling assembly and fitment.

Contact us or email to our sales team directly for your project info@hms1688.com

Stamping Tooling Services

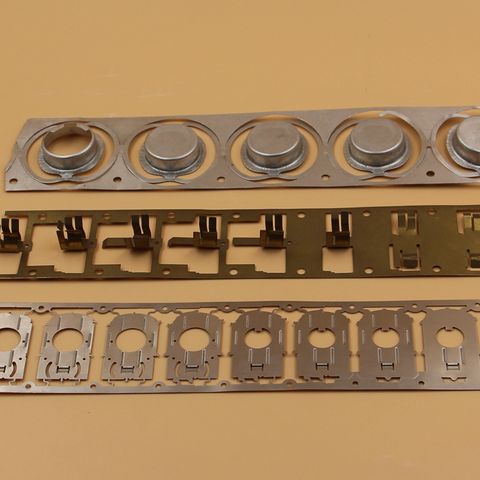

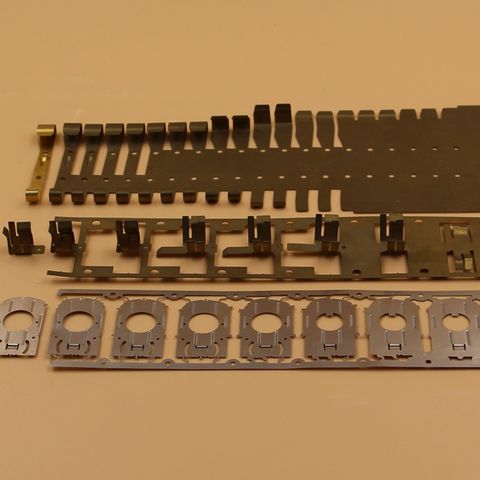

1. Stamping

Stamping includes a variety of sheet metal forming manufacturing processes, such as punching, blanking, embossing, bending, tube bending, shearing, flanging and coining.

2. Deep Drawing

Deep drawing is when draw depth is deeper than the puch width, Here, all of your deep drawn components are produced in one place saving you time and money.

3. Progressive Die

The progressive metal stamping process incorporates numerous methods to produce intricate metal parts and components, including punching, coining bending, and more.

The progressive metal stamping process begins with a metal strip or metal coil being fed into a stamping press that is divided into multiple 'stations'', each with a different stamping tool. As the material moves through the machine, the different tools stretch, cut, or otherwise form the metal into the desired shape, one step at a time. This process is especially suitable for complex metal stamps.

Secondary services

1. Heat treatment to adjust metal physical and chemical properties;

2. Surface treatment: Painting, Powder coating, Zinc plating, Nick plating, Anodizing, Galvanizing, Polishing, etc...

3. Assembly;

4. Customized packaging, oil protection as per needed.

Contact us and just send us your drawing (SolidWorks,ProE,CAD,PDF,DXF...)

Links: Metal Stamping Services | Sheet Metal Fabrication Services | Precision CNC Machining / CNC Milling Services | Metal Welding Services | metal Cutting Services | Metal Bending Service | Surface Finishing | Sheet Metal Enclosures Housing Box And Case Fabrications |